TEXT ABOVE

Heavy duty load cells are used to determine the load applied to an object. This could be the object’s weight, where the load is the force required to lift the object (to counter the force of gravity), or the tension load in a cable or a number of other forces. Heavy duty load cells can operate in virtually any direction (vertically, horizontally, and so on), meaning they are more versatile than traditional scales.

The data from load cells can be used to improve safety and quality assurance in an industrial operation or an entertainment venue. Load cells should be used continuously so that operators can be alerted in real time to any anomalies before they become a safety or quality concern. Therefore, it is important that load cells have a wired power source or long battery life, as they will run constantly (no sleep mode), and are often placed in locations that are not easily accessible, such as ceiling supports and rafters.

No. Crane scales are designed to measure the lifting force against the force of gravity. A load cell or dynamometer, however, can be used to measure tension and pulling forces.

First, consider the estimated loads handled, and then consider what expansions you may experience in the near future. Take your maximum expected load and add 20% as a buffer. The accuracy of the load cell depends on its full scale range, so do not buy a 300 ton load cell when a 20 ton load cell will do.

The Ron 4000 is designed to interface Programmable Logic Controls (PLC), meaning it can be used in feedback loops and integrated into various control systems.

Eilon Engineering Heavy Duty Load Cells

Eilon Engineering has been in the business of designing and manufacturing durable, precision digital hanging scales and heavy duty load cells for lifting and hanging operations. For nearly 50 years, their equipment has been used in a variety of industries and favored by repeat clients, such as NASA, Boeing, Disney and many others.

They offer the Ron 4000 line of analog load cells for sale that range in capacity from 0.5 tons to 300 tons. They are wired (12V-36V DC), meaning there are no batteries to change. Their heavy duty load cells are versatile enough to be used as a hanging load cell for measuring weight or as a tension link load cell for determining pulling forces or tension on a cable. Regardless of the type of load cell required for a specific application, Eilon Engineering’s Ron 4000 line will likely suit these needs.

The Ron 4000 Load Cell is a heavy-duty, force-measuring device designed for the rugged industrial environment. It is available with capacities from 0.5 tons to 300 tons, and is accurate to within +/- 0.1% of the full scale load, making it one of the more accurate load cells on the market.

The loaded cell has no external display, but instead outputs data using a 0-2 V signal or a 4-20 mA signal, both of which are commonly used for computer and Programmable Logic Control (PLC) controllers, as well as many other systems for data acquisition. This allows the load cells to directly interface control decisions, meaning some safety and quality operations can be performed automatically, without the need for an operator to make the decision and perform the action.

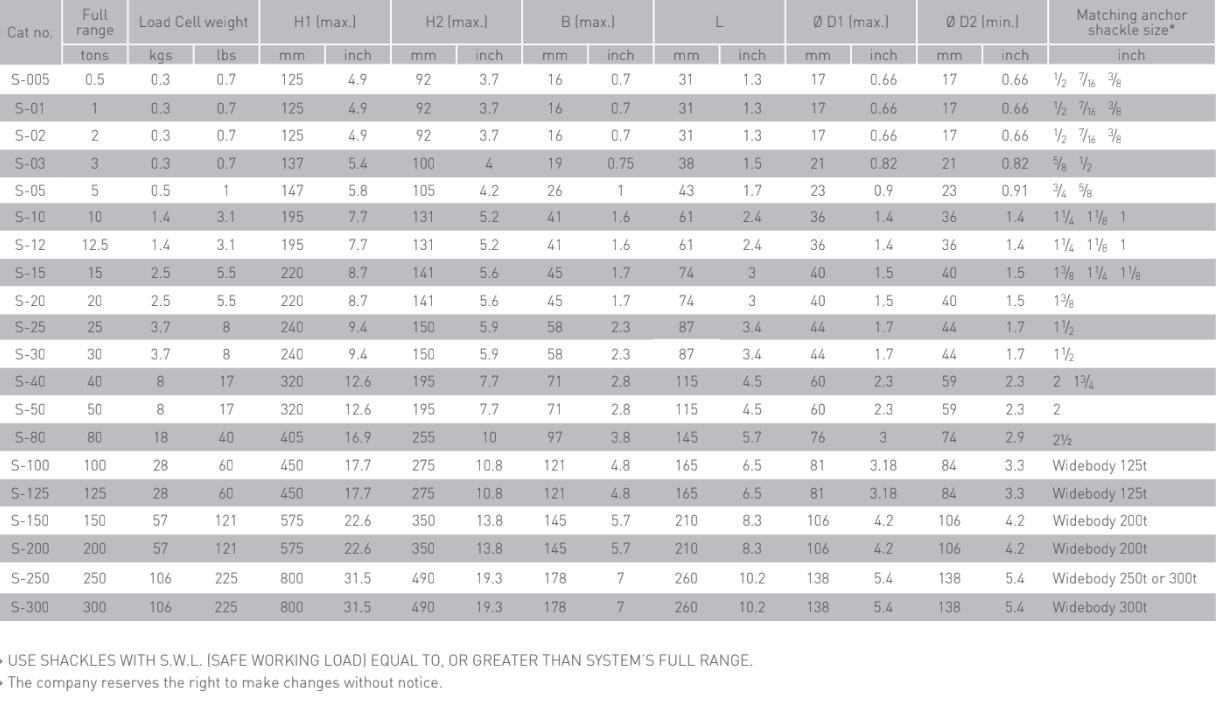

As mentioned above, there are numerous capacities in the Ron 4000 line. The diagram and table below show the available models, with their load capabilities, dimensions and weight.

The Eilon Engineering Advantage

Eilon Engineering has industry-leading experience in the weighing and load measuring market. As such, they have designed their equipment to rigorous standards and with the harsh, industrial environment in mind.

Rugged Design

All Eilon Engineering equipment is designed with a minimum safety factor of 5:1 or even 10:1 safety factors (excluding lifting devices manufactured by other manufacturers). All equipment is constructed from aerospace alloy steel, with some components coated in polyurethane for enhanced corrosion protection. Eilon Engineering’s heavy duty load cells are designed to meet or exceed ASME BTH-1-2017, ASME B30.26 and IEC 61508 fatigue standards ensuring that they will not fail under everyday, repeated use for many years to come.

They are also Ingress Protection (IP) rated to a minimum of IP65, with the wireless models rated to IP67, meaning they are suitable for dusty environments and environments where water spray may be an issue. Each load cell body is also proof tested to 200% capacity.

Ease of Communication

Elion Engineering keeps current with the latest industrial communications protocols while still allowing systems to integrate easily with existing legacy hardware. Depending on the specific model, devices can have USB, RS-232, RS-485 or simple voltage or current output plugs. This allows them to interface everything from desktop computers to PLCs to external LED displays. These can be used for monitoring and data collection, as well as for some control functions that do not require human interaction. With the addition of an optional Bluetooth interface, engineers and technicians can view the data on their smartphones and tablets, improving the portability of the system and its data.

Eilon Engineering can guide you through the process of selecting the proper hanging load cell for your application and facility. Whether you are looking for a load cell for weighing crane loads, a tension load cell for determining the tension on a fishing net, or a dynamic load cell for rapidly-changing load, you can contact Eilon Engineering for more information.

.png) Barcelona Jan 30-Feb 2

Barcelona Jan 30-Feb 2