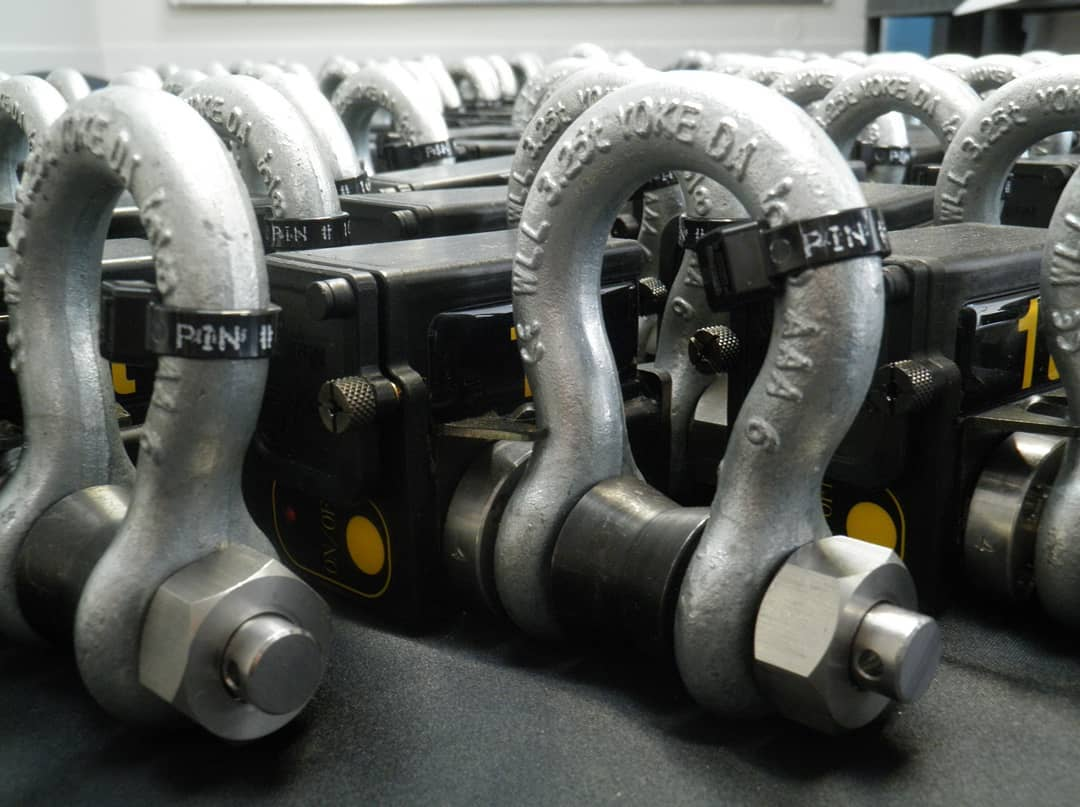

Load Shackles

What are load shackles?

A load shackle or shackle load cell is a specialized piece of equipment that combines the strength of a regular shackle with the ability to measure the force or tension that’s applied to it. Essentially, it’s a heavy-duty shackle with a sensor built into the shackle pin. This sensor can convert the physical strain placed upon the pin into an electrical signal that can then be converted into a unit of measurement to be displayed on a readout.

So while a typical load cell that’s used to measure force would be a separate piece of equipment attached to a shackle, shackle load cells combine them into one single piece of equipment that can both lift and weight. It’s like having two lifting accessories in one.

The advantage of the load shackle over a regular load cell is that it is smaller and allows for less headroom loss.

The load shackle is a versatile piece of rigging equipment and is used in various scenarios: from lifting and rigging operations to marine and construction projects. Their rugged construction allows them to withstand harsh environments while providing accurate and reliable measurements of weight or tension.

How do load shackles work?

Here's a simplified explanation of how they work:

- Load application: When force or weight is applied to the shackle’s pin, the pin’s body deforms ever so slightly.

- Strain gauge conversion: This deformation is sensed by a strain gauge, which is a tiny sensor attached to the pin.

- Signal generation: The strain gauges convert the physical strain into an electrical signal proportional to the applied force.

- Data transmission: This electrical signal is then transmitted via cable or wirelessly to a display unit or data logging system.

By utilizing load shackles, operators gain valuable insights into the forces at play, ensuring safe and efficient lifting operations in a variety of weight-bearing applications.

Load cell shackles can be either wired or wireless. This means that the data is transmitted via a cable or is broadcast through some form of wireless communication, usually either radio frequency transmission or via Bluetooth.

Wireless load shackles allow for both easier installation—no mess cable to run—and additional safety since they eliminate the tripping hazard the cables can pose.

Still, in some applications, a wired system might be the preferred choice depending on the exact nature of the application.

Load Shackles: the guardian angels of rigging equipment

In the realm of rigging—where heavy objects are lifted, lowered, and maneuvered—safety reigns supreme. A single oversight can have catastrophic consequences, putting both riggers and bystanders at risk. This is where load shackles emerge as crucial tools in the safety toolbox, playing a vital role in preventing accidents and fostering a safer work environment.

Why is safety paramount in rigging?

- Catastrophic consequences: A single error can cause an overload, which could lead to equipment failures, dropped loads, and even collapse, potentially causing severe injuries or fatalities.

- Protecting lives: Riggers operate in close proximity to heavy machinery and moving loads. Ensuring their safety is essential.

- Bystander protection: Operations often take place in areas frequented by the public. Maintaining a safe work zone is crucial to prevent harm to bystanders.

How do load shackles contribute to increased safety?

- Real-time monitoring: Load shackles provide real-time data on the weight or tension being exerted, allowing riggers to stay within safe working limits.

- Overload prevention: By monitoring the load, riggers can identify and prevent overloading situations that could lead to equipment failure or structural damage.

- Informed decision-making: The accurate data provided by load shackles empowers riggers to make informed decisions about lifting procedures, angles, and equipment selection.

- Improved communication: Real-time load data can be communicated to other crew members and supervisors, fostering better coordination and awareness in the work zone.

Load shackles also contribute to long-term safety:

- Promoting a culture of safety: By highlighting the importance of accurate load measurement, load shackles help cultivate a safety-conscious mindset within the rigging team.

- Data-driven improvements: The data collected can be used to analyze past operations, identify potential weaknesses, and develop safer rigging practices for future projects.

Load shackles aren’t mere measuring tools—they’re a vital piece of rigging equipment that plays a significant role in protecting riggers, bystanders, and the integrity of operations within the field of rigging. By providing real-time data and promoting informed decision-making, they contribute significantly to a safer and more efficient work environment.

The world’s premier load monitoring system

In 2005, Eilon Engineering launched the Ron StageMaster—the world’s first multi-point load monitoring and overload prevention system specifically designed for use in stage and event rigging. The RSM combines decades of experience in wireless transmission with our expertise in load cell technology.

Not only do we offer the RSM with our classic Eilon load cells, but now it’s available with wireless load shackles as well.

Our shackle pin load cell offers extremely low headroom, lightning-fast installation, and impressive battery life of up to 5000 hours.

Features include:

- Up to 200 load cells per laptop monitoring station and an unlimited number of monitoring stations.

- Tablet and smartphone compatibility allows for portable browsing.

- Longer transmission range: Up to 2/3 mile / 1 km or more if required (optional).

- Real-time load map with all wireless and wired load cells displayed on one laptop screen.

- Continuous unlimited data logging: Downloadable data log of months of continuous measurements.

- Real-time cellular SMS alert on overload occurrence.

Technical Specifications:

- R.F. transmission range: Up to 450' /150m in normal operation conditions (outdoors line of sight). Longer transmission ranges are optional.

- Safety Factor: 5:1 Standard. 10:1 and higher safety factors are available.

- Accuracy: +/- 2% of full range.

- Capacities: from 0.25t to 3.25t

- Functions: Sum, Max, Tare, Zero, Group (LC), Overload detection and alert (visual and audible), Low battery indication, and more.

- Load cell material: High tensile strength, PH stainless steel.

Learn more

Get in touch today to learn more about RSM load shackles:

Phone:

US/Canada/Int'l: 1-888-778-8064

UK: 0800 8620354

Email:

sales@eilon-engineering.com

.png) Barcelona Jan 30-Feb 2

Barcelona Jan 30-Feb 2