Swedish Idol Final (2016)

With a history of pop music success, including multiple Eurovision Song Contest victories, perhaps no country embraces reality song competitions like Sweden. One good example is the well-known Idol franchise, which has been one of the most popular shows on Swedish television since debuting in 2004.

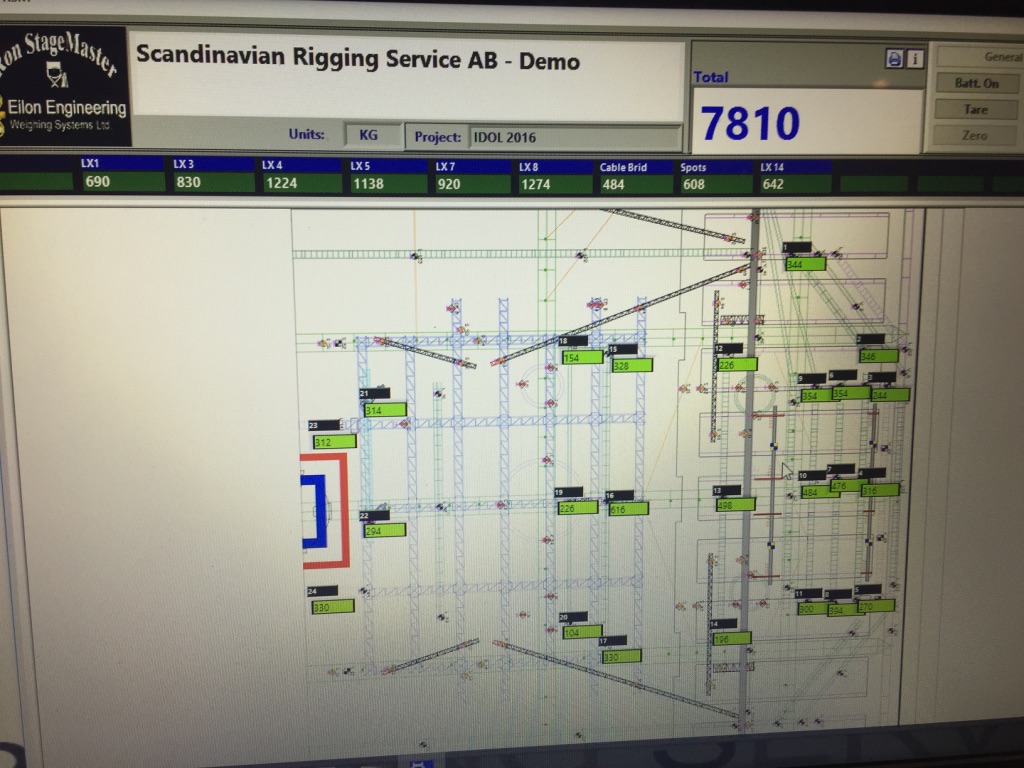

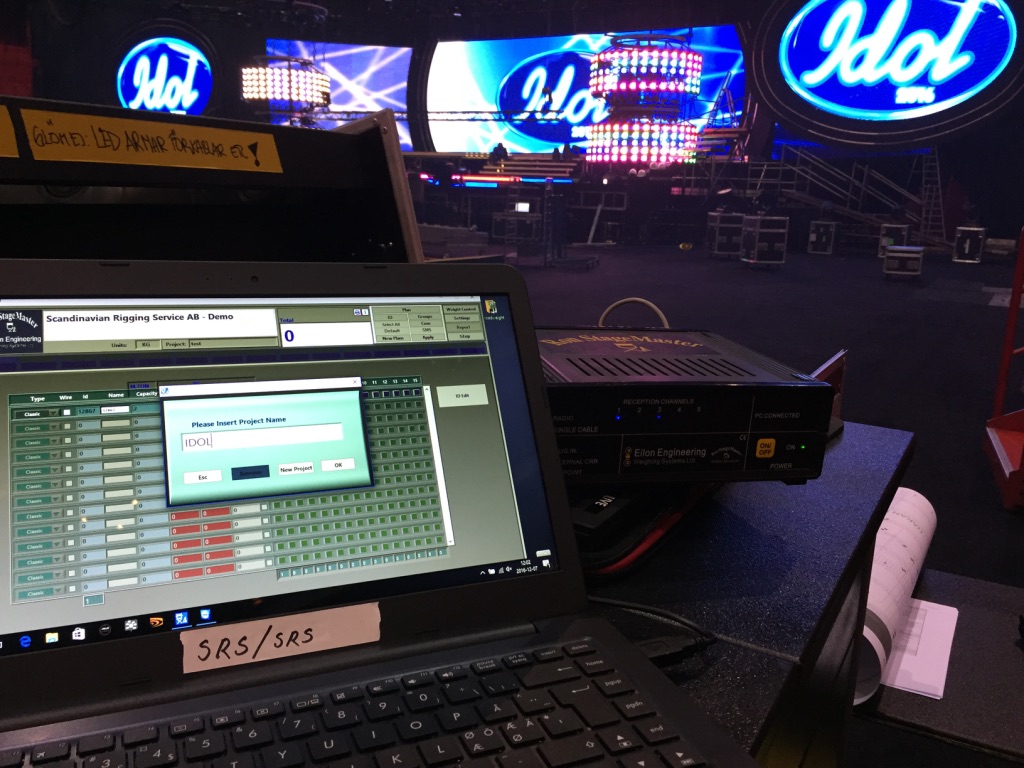

The twelfth Swedish Idol season started airing on TV4 in August 2016 with a finale show held December 8th at the Ericsson Globe Arena in Stockholm. Scandinavian Rigging Service (SRS) has worked on each Swedish Idol Final for the last 10 years, and this year was responsible for the complete rigging from drawings and weight calculations to top rigging supply and rigging personnel. New this year however was the use of Eilon Engineering’s Ron StageMaster load cells to monitor the rig’s weight and distribution.

Greater awareness to use load cells

“There are no requirements to use load cells with large rigs in Sweden,” says Sören Durango, who has owned Scandinavian Rigging Service since 2014. “Not yet, anyway.” Sören does say though that there has been more awareness to use load cells on larger shows in venues like the Globe, an arena that seats 16,000 people. “I have a good relationship with the client as I’ve worked with them many times over the years,” he said. “So I approached them about using Eilon Ron StageMaster load cells on this show, stressing the safety factor involved. They said yes and thought it was a good idea.”

Larger shows, larger rigs

With rigs becoming heavier as shows get bigger each year, venue load limits have become a greater concern. “Rigs are getting closer and closer to the limit of what venues can bare,” Sören says. “On the Idol Final, we had a large PA system with built-in amps plus big video walls and a huge lighting system in the house rig. All together it means a heavier system above people’s heads.”

There were multiple layers to the Idol rig, which was concentrated above the stage rather than spread out in the venue. Consequently, that made it hard to always see what was happening. “I wanted to know 100% what was going on with the rig,” Sören said. "I wanted to know that the rig was okay. It gave me peace of mind to use the Ron StageMaster load monitoring so that when I left the arena at night I could sleep well. It was a real stress reliever.”

Ron StageMaster 6000™ G4 wireless load cell

As the ceiling in the Globe is quite high, approximately 35m, Sören wanted to place all load cells above the hoist in order to get everything controlled. “It was important that the system was live, direct and wireless, otherwise we could not have put the load cell above the hoist, which was at 24m,” he explains. “Wired was not an option because it was 11 meters down to the hoist.” Sören explains that because all hoists used on the show were from another supplier, he didn’t know what type he would be getting and therefore didn’t know the exact spec beforehand.

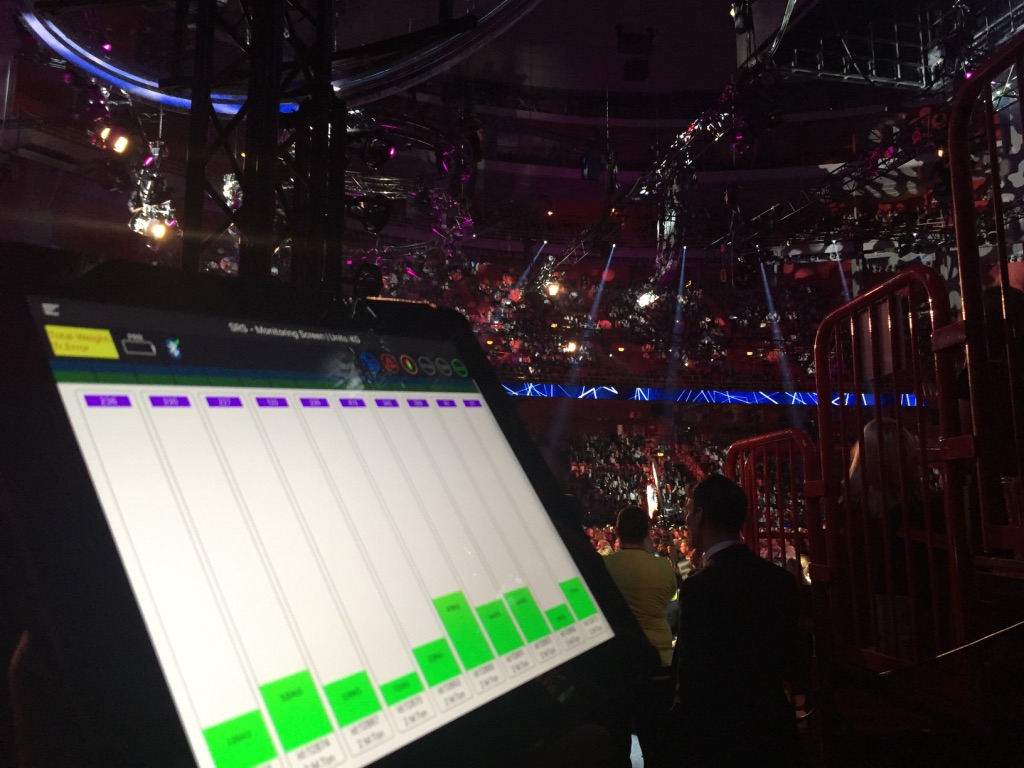

Used to monitor the setup were 24 Ron StageMaster 6000™ G4 wireless load cells run using one CRR and a PC and one PRR with an iPad. In this wireless system, load cells transmit via radio frequency to the Ron StageMaster PRR (Portable Radio Receiver) - a hand-held Bluetooth-compatible load monitoring system for which you simply download the app to a tablet or smartphone. The PRR can monitor up to 40 individual load cells from a single screen and any location. The stationary desk-top version is based on a CRR (Central Radio Receiver) that monitors up to 200 load cells. The quick-to-install plug-and-play system is extremely convenient for riggers, simple to operate, eliminates messy cabling, and has an extremely short response time.

Sören was able to live monitor the setup’s six video walls in order to not overload the house grid where the main PA was also hanging. “Knowing that the calculation was right was absolutely necessary and with load cells you know exactly what hangs there,” he stated. “If I get a wrong number from somewhere, a wrong spec for example, it doesn’t matter. It eliminates the human error, makes my work much safer and is safer for everyone.” He adds that using load cells is also good for his relationship with the venue.

Reduced exposure and minimized liability

Used to monitor the rig for any unexpected shifts in weight from setup to tear down, the Ron StageMaster 6000 G4 load cells provided a level of comfort for everyone involved in the show. By using the safety device, Sören both reduced exposure and minimized liability. Made of aerospace quality, high-strength alloy steel, the Ron StageMaster 6000 G4, like all Eilon Engineering load cells, is fatigue rated to withstand unlimited load cycles without the risk of failure or damage. The Ron StageMaster system can continuously monitor a rig up to 5000 hours, and contains absolutely no standby or sleep modes, which are risky and unacceptable from a safety perspective. The Ron StageMaster system monitors the load 24/7 and has a transmission range of up to several kilometers (optional).

Although Sören has used Eilon Ron StageMaster load cells on events before, the Swedish Idol Final was his first chance to use SRS’s own load cells, which were acquired just prior to the show. He concludes, “Another reason the load cells have been an excellent addition to our inventory is the chance to rent them out when not using them on our own projects.”

See Eilon Engineering at the Prolight + Sound show in Frankfurt April 4-7 on Stand 3.0 E21 (Cast).

For more information contact your local Eilon representative or Noga Eilon-Bahar at:

Noga Eilon-Bahar

neb@eilon-engineering.com

www.eilon-engineering.com

.jpg)

.png) Barcelona Jan 30-Feb 2

Barcelona Jan 30-Feb 2